We can produce Carbon Fiber Rollers in any size you want. The other parts, except the bearing parts, are completely carbon fiber. They have many advantages over conventional steel or aluminum rollers. Its high strength compared to its low weight brings with it advantages such as less vibration, longer bearing life, fewer failures and maintenance costs.

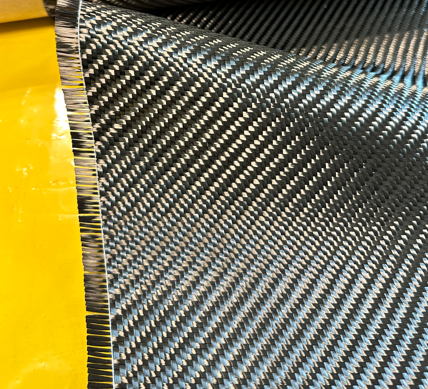

We can produce Carbon Fiber Rollers in any size you want. The other parts, except the bearing parts, are completely carbon fiber. They have many advantages over conventional steel or aluminum rollers. Its high strength compared to its low weight brings with it advantages such as less vibration, longer bearing life, fewer failures and maintenance costs.Higher roller speeds will be possible when Carbon Fiber Rollers and Carbon fiber rollers replace traditional steel or aluminum rollers, and higher line speeds will be achieved to make production more efficient. With carbon fiber cylinders, breaks will be reduced, less starting waste will be generated and material wraps in breaks will be reduced thanks to better tension control on the machines. These improvements in shaft and roller performance directly affect productivity and increase machine efficiency.

Advantages of Carbon Fiber Roller

Advantages of light weight,

Less bearing wear

Longer bearing life

Easier and safer use

Advantages of High Rigidity,

Less coffee

Less web wrinkling.

Longer bearing life.

Faster line speed with less vibration (Higher critical speed).

More efficiency and better product quality.

Less mesh creases at wider apertures

Advantages of Low Moment of Inertia,

The rollers rotate at line speed

Less network scratches

Reduction in cylinder wear

Destroys static electricity

Responds faster to changes in the line

Fewer web breaks

Less startup waste

Less web wrapping in a web copy

Prolongation of cylinder life and reduced coating thickness.

More accurate transducer measurements

More precise tension control

Fewer platen tabs

Higher quality wrapped rolls with less air drag

You can contact us to produce carbon fiber rollers with different sizes.